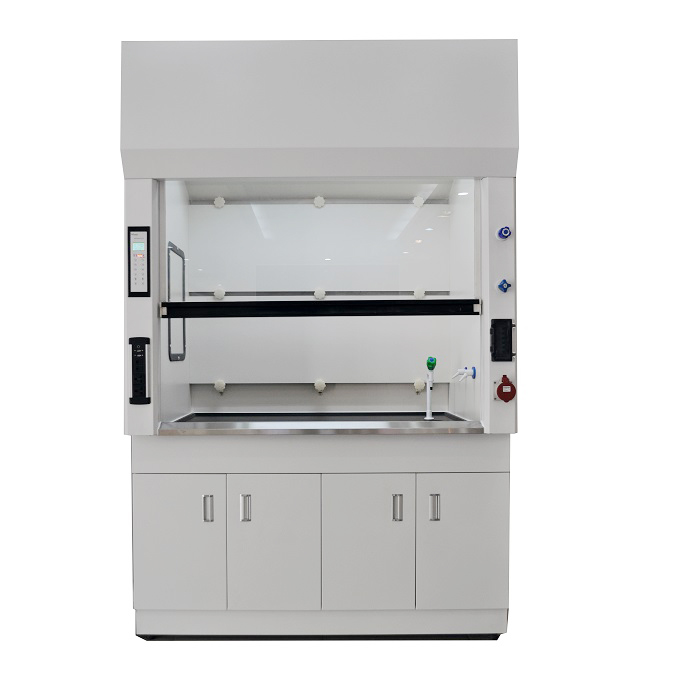

Laboratory Fume Hood Cupboard

A laboratory fume hood is a ventilation device designed to limit exposure to hazardous or toxic fumes, vapors, or dust for laboratory personnel. It consists of a partially enclosed work area, a movable sash window, and an exhaust system that draws air from the work area and discharges it outside the building. This setup provides protection for both the user and the environment, and offers a controlled space for experiments involving volatile or corrosive substances.

Fume hoods come in various types, including chemical, biosafety, ductless, floor-mounted, and special application hoods, tailored to meet the specific needs and applications of different laboratories. Ready to enhance the safety of your laboratory? Explore our range of fume hoods at Hoffen Egypt today! By choosing the right fume hood, you ensure your lab’s safety and efficiency.

Contact us now to find the perfect fume hood solution for your lab’s unique requirements and make sure you are compliant with all safety regulations. Don’t compromise on safety—get in touch with Hoffen Egypt for expert advice on fume hood installations, in addition to other laboratory furniture essentials such as eyewash stations, safety cabinets, and lab benches.

Fume Hood (Automatic)

Essential for safeguarding laboratory personnel from dangerous substances, an automated fume hood is a critical apparatus. Rigorously engineered and validated across diverse scenarios, it guarantees the well-being and security of the workspace, particularly when handling highly perilous and combustible compounds. Operating on sophisticated airflow management and responsive sash adjustments based on operator movements, it not only conserves energy but also optimizes ventilation efficiency. Furthermore, it boasts a robust fire detection and suppression system, swiftly mitigating any potential fire outbreaks within the enclosure, thus mitigating harm and environmental risks. Ensure the utmost safety and efficiency in your laboratory operations by integrating an automatic fume cupboard from Hoffen Egypt.

Fume Hood (Manual)

The streamlined configuration of a fume hood plays a crucial role in managing and guiding airflow within the enclosure, guaranteeing the efficient capture and expulsion of hazardous fumes, gases, or particles. This innovative design fosters a uniform and regulated airflow trajectory, effectively containing contaminants and averting their dispersion into the laboratory or workspace. Moreover, an aerodynamically optimized fume hood aids in reducing turbulence and eddies within the enclosure, thereby enhancing the overall efficacy of the ventilation system. By integrating such a design, you not only ensure compliance with TLV (Threshold Limit Value) standards, safeguarding users from harmful chemical exposure, but also optimize operational safety and efficiency. Elevate your workspace standards by incorporating an aerodynamically engineered fume hood today.

In conclusion, fume hoods are essential for maintaining safety in laboratories. Their aerodynamic design effectively captures and removes harmful substances, ensuring a safe working environment. By minimizing turbulence and adhering to safety standards, they provide peace of mind for users. Investing in a quality fume hood is crucial for maintaining safety and efficiency in laboratory operations.

Home » Fume Hood